ig

dir

estudio

Baja California 360,

Colonia Condesa,

CDMX.

Mexico as a country has achieved an important experience when it comes to the manufacturing of certain materials such as wood, metal, and clay. Time has passed by and Mexico has learned how to work with these materials, the limits of each one, and most importantly how to push these limits to achieve new and unexpected results.

However, it is really important to “peek at our neighbor’s work” and see what materials they are working with, how are they pushing their limits and what can we learn from their experience in this path.

This week we wanted to talk about the additive manufacture, where is it going, why has it become a sustainable practice, its advantages as well as its disadvantages. All of this with industrial designer Adam Weaver, someone who we consider an expert on this topic.

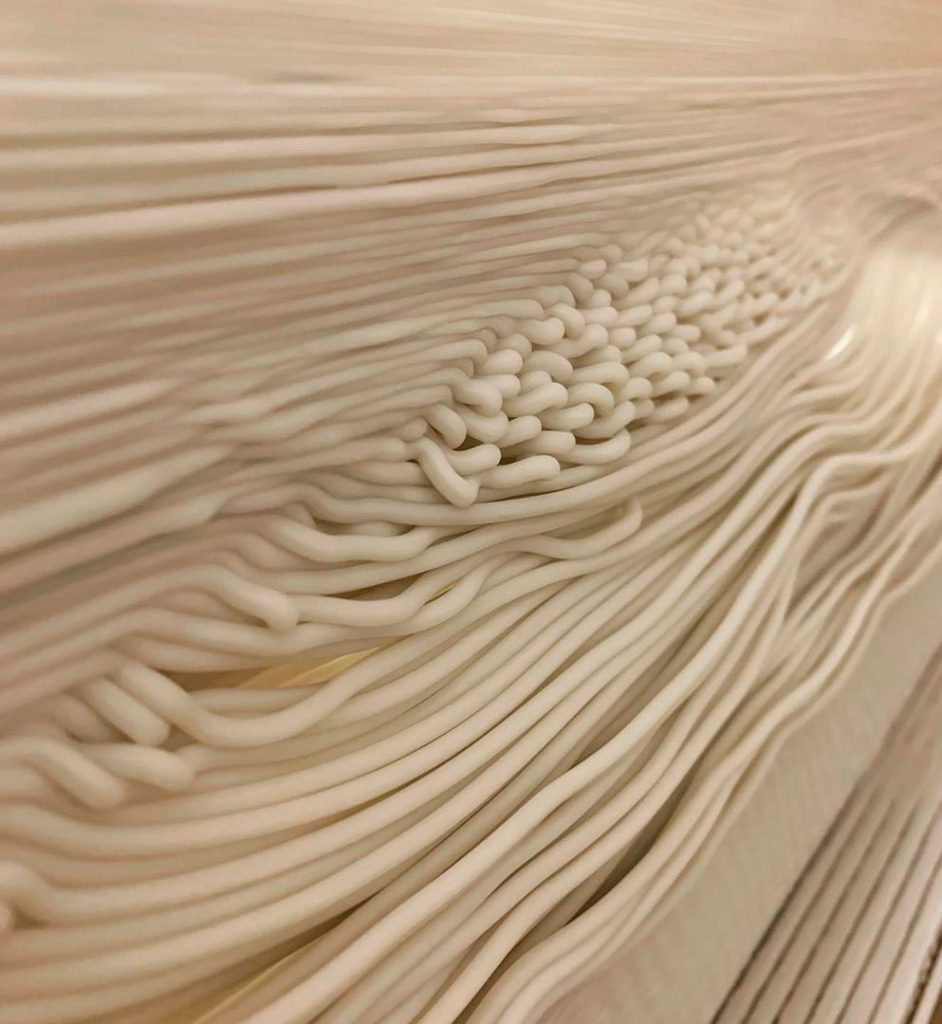

Additive manufacturing or 3d printing in furniture is the next evolution of the 4 fourth industrial revolution which is based in a decentralized hub of manufacturing and distribution model that allows for a smaller more agile manufacturing process into smaller more localized factories. These two things allow for individuals to better tailor their furniture for their lives. So, the main advantages are higher quality, more customizable locally influenced, and created pieces of furniture.

A: Currently this is a two-sided thing, where one side of additive manufacturing is still using very harsh and toxic materials to create never before see objects, and the other side is pushing the envelope of upcycling biopolymers and post-consumer waste. Currently, I am focused purely on biopolymers which are very sustainable. I’m utilizing hemp, PLA, sawdust, and baking flower material pallet. All of which biodegrade or can be upcycled. So, my point of view is 3d printing is truly working at the forefront of sustainability.

A: It’s best to have a great mechanical engineer at hand or architect, as chairs are much like bridges, but an engineering or builder mindset is all you truly need with a firm grasp of mathematics and programming.

A: For additive manufacturing, you are going to have to take a course in additive manufacturing, 3d modeling, or just jump right in and experiment until you master the process and materials. There is a lot that goes into this profession though from material science, design processes, human factors, etc. and that you should truly go to a school that offers an industrial design program. This will allow you to span the depths of different fields that it takes to craft an object into reality.

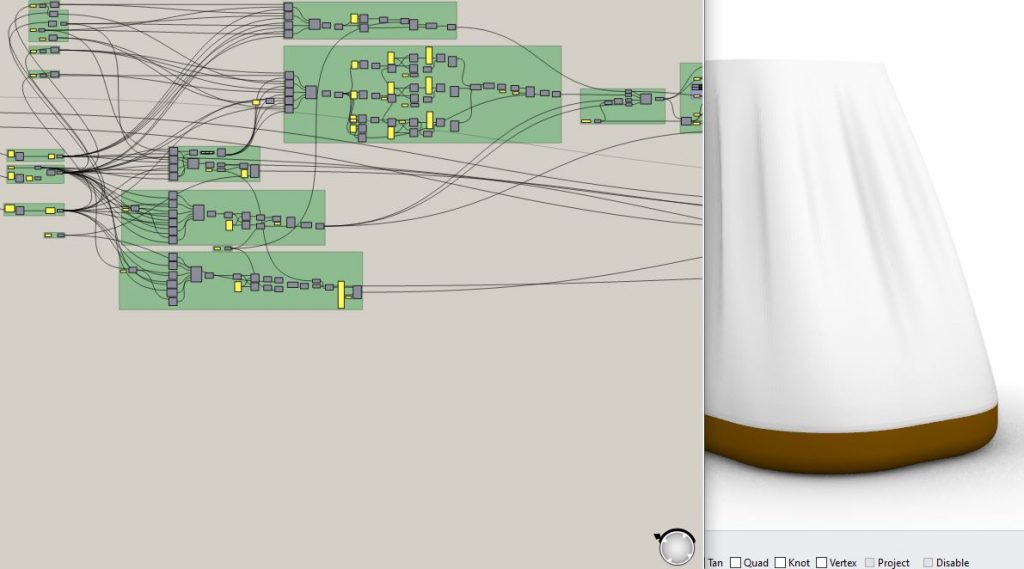

A: I feel the biggest impact that the digital realm brings is the way we play within a 3d space, that is to say, “what if there was no need for seams or draft angles to your designs?” It’s a liberating theory and practice, but paradoxically you need your mind to stop and focus it’s the brilliance to create something functional and not just abstractions of forms.

A: We use a few digital tools that are within Grasshopper and Fusion cad tools, but most of the learnings come from the small-scaled prototypes we print from the iteration process. We actually get them to hold amazing amounts of weight and other forces.

A: The future is always looking at the past in furniture and this is a hard thing to predict. We as consumers live between two worlds, the world of the digital future where anything is possible and the other world of 18th-century buildings we have to style, which makes this a tough question. My future of furniture is purely sustainable, ergonomic, and chic.

A: Food is going to be the future of 3d printing and custom printing foods. You are seeing this now just starting with major fast-food brands like KFC. The future of the designers’ realm is not only just visual form, it’s textural and flavored.

This was our first blog post in English. If you enjoyed it and would love to read more about our content please let us know.💖

With love, Moblog.